Tungsten Suppliers

Tungsten has great high temperature strength, the lowest vapour pressure of all metals, excellent thermal and electrical conductivity and very low thermal expansion up to the highest temperatures.

Tungsten has great high temperature strength, the lowest vapour pressure of all metals, excellent thermal and electrical conductivity and very low thermal expansion up to the highest temperatures.

All of our refractory metals such as Tungsten are supplied by PLANSEE Group of Companies based in Reutte, Austria.

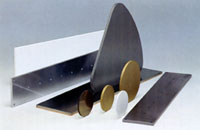

Tungsten Alloys

Pure tungsten is difficult to machine. However copper tungsten alloys improve the machinability of tungsten considerably.

Tungsten and W/Cu alloys are used extensively as electrical contacts, radiation shields and because of its high density is often used as balance weights (camshafts).

More information about tungsten

Tungsten, also known as wolfram, is a chemical element with the chemical symbol W and atomic number 74.

A steel-gray metal, tungsten is found in several ores, including wolframite and scheelite. It is remarkable for its robust physical properties, especially the fact that it has the highest melting point of all the non-alloyed metals and the second highest of all the elements after carbon.[3] Tungsten is often brittle[4] and hard to work in its raw state; however, if pure, it can be cut with a hacksaw.[5] The pure form is used mainly in electrical applications, but its many compounds and alloys are used in many applications, most notably in incandescent light bulb filaments, X-ray tubes (as both the filament and target), and superalloys. Tungsten is also the only metal from the third transition series that is known to occur in biomolecules, and is the heaviest element known to be used by living organisms.[6][7]

Characteristics

In its raw form, tungsten is a steel-gray metal that is often brittle and hard to work, but, if pure, it can be worked easily.[5] It is worked by forging, drawing, extruding, or sintering. Of all metals in pure form, tungsten has the highest melting point (3,422 °C, 6,192 °F), lowest vapor pressure and (at temperatures above 1,650 °C, 3,002 °F) the highest tensile strength.[13] Tungsten has the lowest coefficient of thermal expansion of any pure metal. The low thermal expansion and high melting point and strength of tungsten are due to strong covalent bonds formed between tungsten atoms by the 5d electrons.[14] Alloying small quantities of tungsten with steel greatly increases its toughness.[3]

Applications

Because it retains its strength at high temperatures and has a high melting point, elemental tungsten is used in many high-temperature applications,[32] such as light bulb, cathode-ray tube, and vacuum tube filaments, heating elements, and rocket engine nozzles.[5] Its high melting point also makes tungsten suitable for aerospace and high-temperature uses such as electrical, heating, and welding applications, notably in the gas tungsten arc welding process (also called tungsten inert gas -TIG- welding).

Due to its conductive properties, as well as its relative chemical inertia, tungsten is also used in electrodes, and in the emitter tips in electron-beam instruments that use field emission guns, such as electron microscopes. In electronics, tungsten is used as an interconnect material in integrated circuits, between the silicon dioxide dielectric material and the transistors. It is used in metallic films, which replace the wiring used in conventional electronics with a coat of tungsten (or molybdenum) on silicon.[30]

The electronic structure of tungsten makes it one of the main sources for X-ray targets,[33] and also for shielding from high-energy radiations (such as in the radiopharmaceutical industry for shielding radioactive samples of FDG). Tungsten powder is used as a filler material in plastic composites, which are used as a nontoxic substitute for lead in bullets, shot, and radiation shields. Since this element's thermal expansion is similar to borosilicate glass, it is used for making glass-to-metal seals.[13]

The hardness and density of tungsten are applied in obtaining heavy metal alloys. A good example is high speed steel, which may contain as much as 18% tungsten.[34] Superalloys containing tungsten, such as Hastelloy and Stellite, are used in turbine blades and wear-resistant parts and coatings. Applications requiring its high density include heat sinks, weights, counterweights, ballast keels for yachts, tail ballast for commercial aircraft, and as ballast in race cars for NASCAR and Formula One. It is an ideal material to use as a bucking bar for riveting, where the mass necessary for good results can be achieved in a compact bar. In armaments, tungsten, usually alloyed with nickel and iron or cobalt to form heavy alloys, is used in kinetic energy penetrators as an alternative to depleted uranium but may also be used in cannon shells, grenades and missiles to create supersonic shrapnel. High-density alloys of tungsten may be used in darts (to allow for a smaller diameter and thus tighter groupings) or for fishing lures (tungsten beads allow the fly to sink rapidly). Some types of strings for musical instruments are wound with tungsten wires. Its density, similar to that of gold, allows tungsten to be used in jewelry as an alternative to gold or platinum.[5][35] Its hardness makes it ideal for rings that will resist scratching, are hypoallergenic, and will not need polishing, which is especially useful in designs with a brushed finish.[36]

Tungsten compounds are used in catalysts, inorganic pigments (e.g. tungsten oxides), and as high-temperature lubricants (tungsten disulfide). Tungsten carbide (WC) is used to make wear-resistant abrasives and cutters and knives for drills, circular saws, milling and turning tools used by the metalworking, woodworking, mining, petroleum and construction industries[3] and accounts for about 60% of current tungsten consumption.[37] Tungsten oxides are used in ceramic glazes and calcium/magnesium tungstates are used widely in fluorescent lighting, while tungsten halogen bulbs are frequently used to light indoor photo shoots, and special negative films exist to take advantage of tungsten's unique disentangling properties. Crystal tungstates are used as scintillation detectors in nuclear physics and nuclear medicine. Other salts that contain tungsten are used in the chemical and tanning industries.[13]

Source: Wikipedia.org